FIRETECH supplies landing valves, pressure regulating valves, breeching inlets, angle hose valves, and other valves. All of our products are suitable for a range of dry risers and will play an important role in your fire defense.

| Model | Size | H(mm) | W(mm) | Inlet | Outlet |

| FT06-201-00 | DN50 | 290 | 155 | 165 | BS336 |

| FT06-201A-00 | DN65 | 300 | 155 | 185 | BS336 |

| Standard | Certificate to BS 5041-1 |

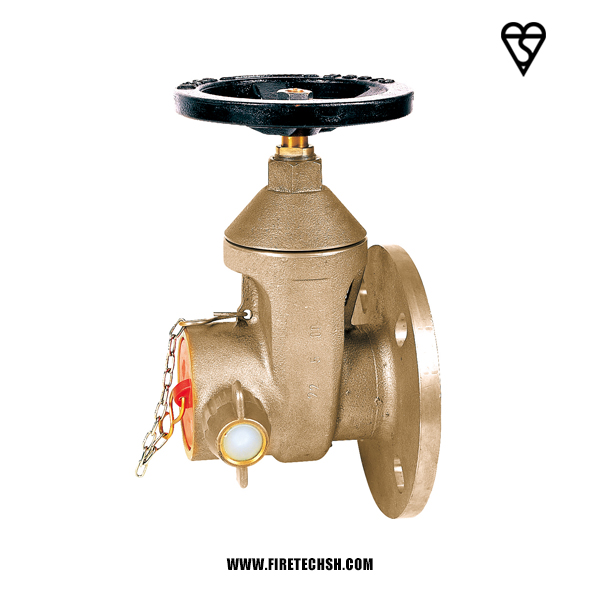

| Body | Copper alloy, Thinkness>=4mm |

| Handwheel | Grey cast iron alloy |

| Blank cap | Copper alloy or Plastic |

| Inlet | Flanged |

| Outlet | Female instantaneous to BS336 |

| Surface | Red or yellow painting |

| Test pressure | 30 bar |

| Fully open | 4.5 turns |

The design and construction of the hydrant valves are strictly in accordance with BS5041 standards.

The selection of materials in the manufacturing of the valve are all of corrosion resistant, tough and durable. This ensures the product long-life plus providing an efficient service in the time of need.

The valve metal to metal seating are precisely machined so as to provide the shut-off of the valve to have a water-tight sealing. Every hydrant valve manufactured is hydro statically tested to 16.5 bars and 22.5 bars for the valve seat and body respectively.

The internal casting finishes of every valve is of high quality ensuring a low flow restriction that meets the standard's water flow test requirement. The hydrant valve comes complete with standard "black" plastic blank cap and chain. Alternative blank caps made of aluminium, brass or gunmetal are also available on request.

Compact and elegant design with excellent flow characteristics.

High quality casting finishes.

Precise machining for metal to metal seating provide leak-proof.

Corrosion resistant and quality materials used for durability, long-life and efficiency.

Maintenance free.